Inner Diameter (ID) grinding, also known as Internal Diameter Grinding, Inside Diameter Grinding, Bore Grinding, and Precision Internal Grinding, is a meticulous machining process where the material is precisely removed from the inside diameter of a cylindrical or conical workpiece. This operation intricately shapes the internal surface of a cylindrical workpiece, which rotates as an abrasive tool machines its inner circumferential surface in the opposite direction.

The Process of ID Grinding in Houston

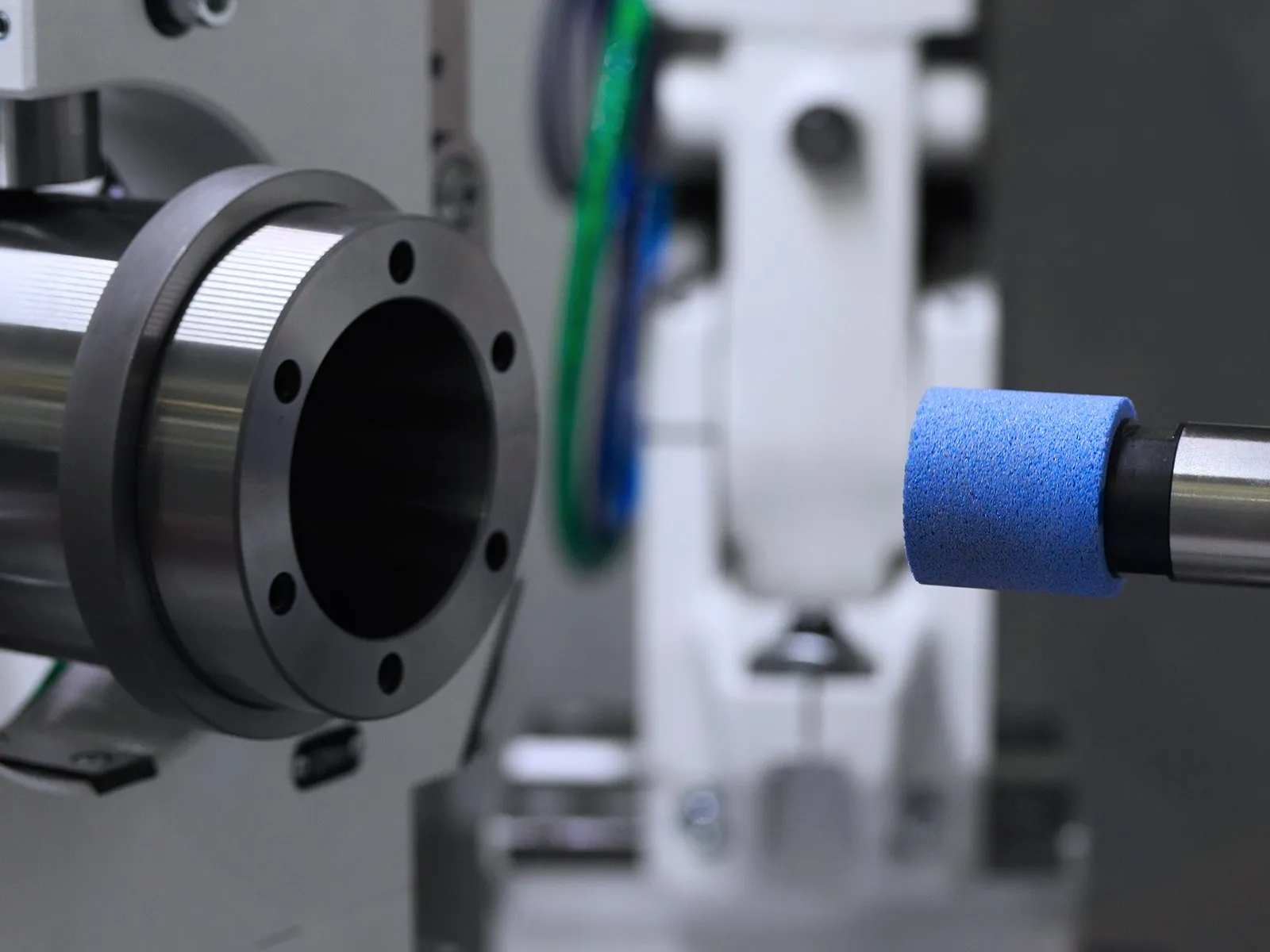

The ID grinding process in Houston utilizes an internal grinding machine equipped with a grinding wheel that is instrumental in removing the final stock to a finish dimension and surface finish. The machine and the grinding wheel must be up to the task, capable of handling the precision and intricacies of the process, making it an optimal choice for industries like aerospace and automotive.

The grinding wheel is usually made of aluminum oxide abrasives, known for their hardness and durability. The process also requires multiple work-holding options to secure the workpiece during grinding, ensuring accurate concentricity and precise inch tolerance.

Inner Diameter Grinding Capabilities Near Me

With its ability to offer precision and tight tolerance control, ID grinding is an optimal choice for machining intricate aerospace assemblies and components in Houston. By improving the quality of the finished product, ID grinding plays a significant role in enhancing production operations.

Notably, ID grinding can manage parts from .250" to 20" inside or outside diameters by 14 inches deep, perfecting faces, tapers, and radii with exceptional precision. This process also excels in grinding multiple features of a part on one chucking, leading to fewer setups, diminished wasted time in handling parts, and more accurate runout, perpendicularity, and concentricity.

To meet these demanding requirements, state-of-the-art grinding machines, such as the Okamoto IGM-2M, are deployed in ID grinding. These machines are engineered to withstand rigorous high-volume production while upholding exceptional accuracy and dimensional repeatability.

Applications of Inner Diameter Grinding in Houston

ID grinding finds extensive use across diverse components in Houston, including bearings and bushings, aerospace components, shims, pins, and rods. Specialized aerospace grinding machines, such as the Aerospace centerless grinding machine, Aerospace cylindrical grinding machine, Aerospace shaft grinding machine, Aerospace surface grinding machine, and Aerospace vertical grinding machine, are harnessed to offer the highest quality aerospace grinding services.

Some of the common applications of ID grinding include:

- Oil and Gas drilling components

- Bearings and bushings

- Aerospace components

- Shims

- Pins

- Rods

Materials and Tolerances

The materials that can be processed through ID grinding span from metals to ceramics, composites, plastics, and rubber, with finishes including hard chrome and coatings. The process can accommodate inside part diameters of .200″ to 36″ and outside part diameters of up to 48″. The highest tolerance achievable is up to +/-.0002″, underscoring impressive precision.

Quality Assurance in ID Grinding

Rigorous quality control standards are integral to the ID grinding process in Houston. Procedures encompass visual inspections, dimensional measurements, hardness testing, and numerous other tests to ensure components meet all required specifications. Full documentation of the grinding process is provided for complete accuracy and quality control, often complying with ISO and Mil-Spec standards.

ID grinding is a complex yet indispensable process in precision machining. Providing high-quality, fast services is pivotal in ensuring that components meet exact specifications and necessary safety requirements. Whether for aerospace assemblies or other intricate components, ID grinding offers an effective solution to meet diverse industry standards and requirements.

Choose Grindmasters Inc., in Houston, Texas for Your Bore Grinding and Inner Diameter Grinding Needs

Contact Us

Grindmasters Inc.

11203 Jones Rd W

Houston, TX 77065

Phone: 713-933-4433

Email: adrian@grindmastersinc.com