Nestled in Houston's industrial hub, Grindmasters Inc. is the go-to for all your Blanchard grinding needs. Setting the benchmark for quality and precision, we've become Houston's top choice for Blanchard grinding services.

Understanding Blanchard Grinding

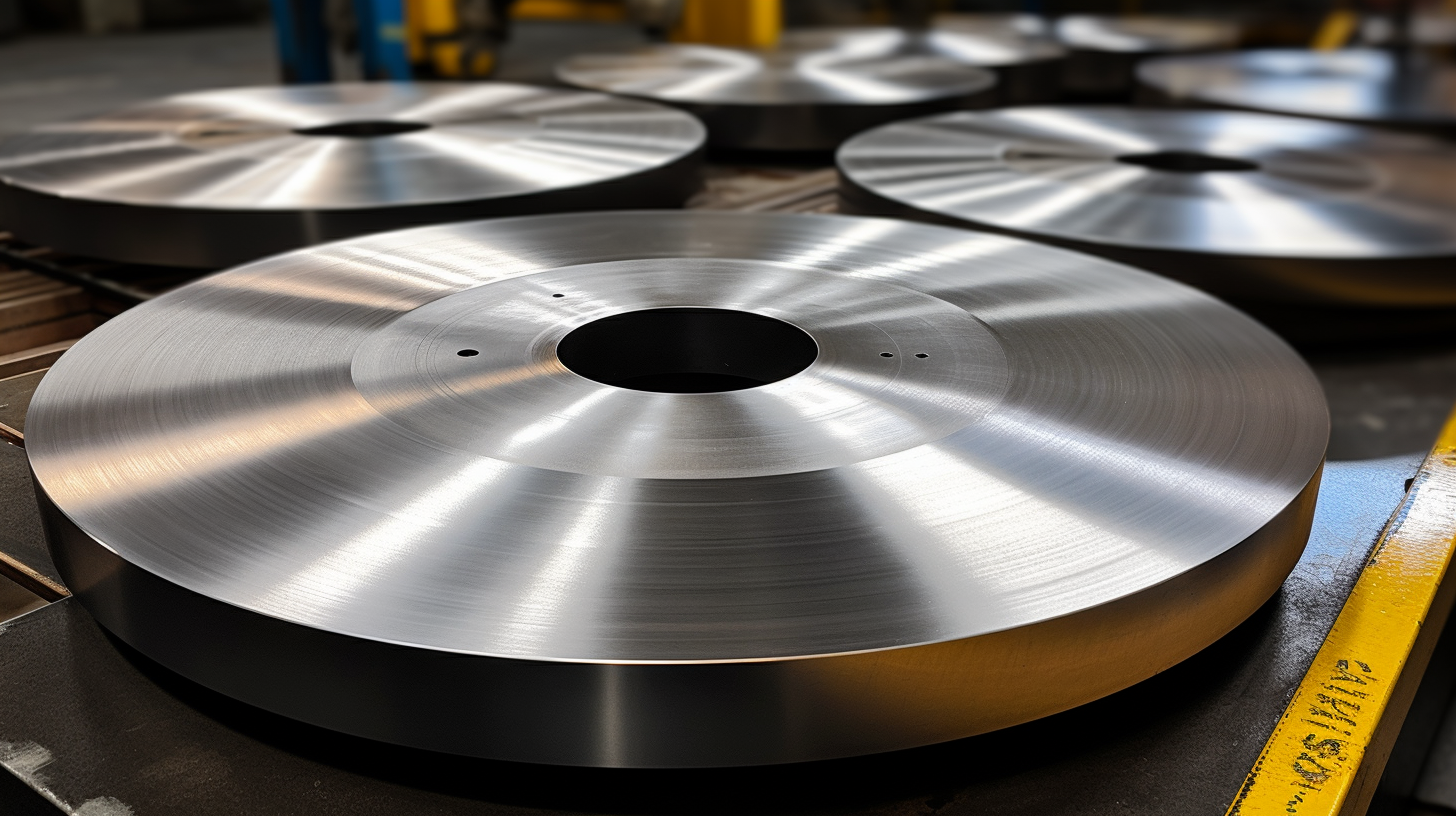

Blanchard grinding, often referred to as surface grinding, utilizes a vertical spindle and rotary table machine for achieving precision in flatness and finishes. The term originates from the most common machines of this type made by Blanchard, but similar machines are also produced by other manufacturers. These machines are versatile and can handle a range of shapes, sizes, and materials.

The essence of Blanchard grinding is its ability to produce very accurate flat surfaces and fine finishes. The machine's design, with its vertical spindle and rotary table, allows for grinding a wide variety of materials. Through innovative fixturing techniques, these grinders can handle diverse shapes and sizes.

The grinding process involves a combination of the machine's capabilities and the operator's expertise. Factors such as load areas, configurations, feeds, speeds, and motor loads play a crucial role in achieving the desired results. For instance, optimal table loads vary based on the size of the machine, and achieving the right balance between table speed and downfeed rate is paramount.

In addition to the machine's capabilities, the choice of abrasive is critical. Abrasives, which do the actual cutting, are typically made of either Aluminum Oxide or Silicon Carbide. The selection of the abrasive grain is determined by the material being ground, with different grains offering varying properties of hardness, friability, and sharpness. The bond, which holds the abrasive grain in the wheel, can be either vitrified or resin.

In the realm of Blanchard grinding, understanding the intricacies of the process and the machine's capabilities is essential for achieving precision and efficiency. Whether you're grinding soft steels or hard materials like tool steels and stainless steel, the right combination of machine settings and abrasive selection will ensure optimal results.

Use Cases for Blanchard Grinding:

Blanchard grinding, commonly known as surface grinding, employs a vertical spindle and rotary table machine for various applications:

Size & Precision: Blanchard grinders are available in various sizes, ensuring precision across different scales.

Material & Shape Flexibility: These machines can accommodate a diverse range of shapes and materials, from complex geometric pieces to simple flat surfaces.

Optimal Load Areas: For solid parts, maintaining table loads between 35% to 50% ensures consistent and efficient grinding.

Efficient Feeds & Speeds: Adjusting feed rates according to the area being worked on ensures optimal grinding efficiency.

Motor Load Monitoring: Integrated ammeters allow operators to monitor the machine's operational efficiency.

Performance Measurements: Metrics such as the 'G' Ratio provide insights into the efficiency and cost of the grinding operation.

Abrasive Selection: The choice between abrasives like Aluminum Oxide or Silicon Carbide is determined by the material being processed.

Maintenance: Regular maintenance ensures the longevity and accuracy of Blanchard grinders.

Advantages of Blanchard Grinding:

Precision & Versatility: Blanchard grinding ensures both precision in flatness and versatility in finishes.

Diverse Applications: These machines can handle a wide range of shapes, sizes, and materials, making them invaluable in various grinding scenarios.

Efficient Load Areas: Maintaining table loads between 35% to 50% for solid parts optimizes the grinding process.

Balanced Feeds & Speeds: A harmonious balance between table speed and downfeed rate ensures optimal material removal and efficiency.

Motor Load Monitoring: Ammeters in these machines enable operators to ensure the grinder operates at its optimal capacity.

Performance Metrics: Metrics like the 'G' Ratio and Rate of Removal allow for effective monitoring of operations.

Abrasive Selection: The grinding process can be customized by selecting the appropriate abrasive for the material in question.

Maintenance & Precautions: Proper maintenance and regular checks ensure the smooth and safe operation of these machines.

Frequently Asked Blanchard Grinding Questions:

What is Blanchard grinding? Blanchard grinding, a technique developed in the early 1900s by the Blanchard Machine Company, is a form of rotary surface grinding. Unlike other grinding methods, Blanchard grinding uses a vertical spindle combined with a rotary table, making it distinctively efficient. The process is known for its ability to remove significant amounts of material quickly while leaving behind a unique cross-hatched pattern. This pattern not only adds to the aesthetic appeal but also enhances the functionality of the surface, ensuring better adhesion for coatings or paints.

How does Blanchard grinding differ from precision grinding? The primary distinction between Blanchard and precision grinding lies in their objectives and the materials they handle. Blanchard grinding is the go-to method for materials with larger surface areas. It emphasizes rapid stock removal, especially when one side of a material needs to be ground down. Precision grinding, as the name suggests, is all about finesse. It's tailored for materials with smaller surfaces and aims to achieve a superior, mirror-like finish with high parallelism. While Blanchard is about bulk and speed, precision grinding is about detail and accuracy.

What's the tolerance level for Blanchard grinding? In the world of grinding, tolerance levels dictate the precision and accuracy of the final product. The industry standard for Blanchard grinding is a tolerance of up to 0.001â€. However, at Grindmasters Inc., we're not just about meeting standards; we're about setting them. We consistently push for even tighter tolerances, often achieving results that surpass client expectations. Why? Because in our line of work, every thousandth of an inch can make a difference, ensuring that the final product is not just good, but exceptional.

How much material can Blanchard grinding remove? Blanchard grinding is renowned for its material removal capabilities. At Grindmasters Inc., our machines and expertise allow us to remove between 0.25 to 0.5 inches from steel in a single pass. This means projects that might take days using other methods can be completed in hours with Blanchard grinding. And here's the kicker: even with such rapid removal, we never compromise on the quality of the finish. Our clients get a quick turnaround without any drop in the excellence they've come to expect from us.

Contact Grindmasters Inc.:

Have a Blanchard grinding project for us? Reach out to Grindmasters Inc. today!

- Location: 11203 Jones Rd W, Houston, TX 77065

- Phone: 713-933-4433

- Email: adrian@grindmastersinc.com